Lead-free Wave Soldering ETS-300

Wave soldering

结构紧凑,占地面积小,节省场地; PC+PLC控制系统;红外预热,热效率高,温度均匀性好; 喷雾采用步进马达驱动,更加平稳可靠;采用缩小容量锡炉,降低成本投入。

- Product Details

- Related Products

Characteristics:

1. Transportation:Input board direcly. Stainless ste chain conveyor,durable and special design for aluminum alloy track. Applied floating track for different stages for preventing deformation.

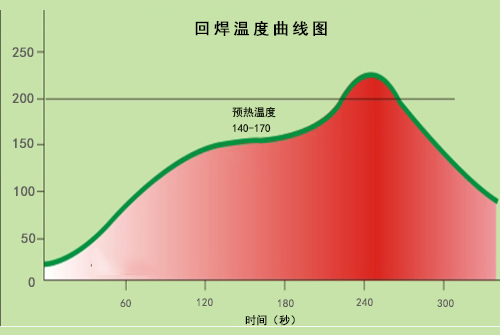

2. Preheating system: Drawer-type energy-saving design, IR preheating, PID mode temperature control, temperature control accuracy can reach±2℃, the temperature dropping is ≤5°C between preheating zone and soldening zone.

3. Flux spraying system: Managed by digital control. The motion of the spray nozzle is controlled by stepper motor. Flux supply is controlled automatically for optimized effect. Exhausting and fiter system installed on the top.

4. The solder pot is made by cast iron with anti-corrosion ceramic coating equipped with two low flow rate nozzles.

5. Forced air cooling system.

6. PC+PLC control system, Windows 7 operating system, Chinese/English operation interface, process profile/data automatic storage function, lower or higher flux level alarm; lower tin level alarm.

Product

Product

home

home

TEL:0510 - 81029991

TEL:0510 - 81029991 Mail:changqixiao@163.com

Mail:changqixiao@163.com Address:No. 189, Changba Road, Chang'an, Yanqiao Street, Huishan District, Wuxi City

Address:No. 189, Changba Road, Chang'an, Yanqiao Street, Huishan District, Wuxi City