Lead-free double wave soldering machine XD-250M-LF

Wave soldering

新颖,采用喷塑工艺不掉漆,经久耐用。

- Product Details

- Related Products

Technical features:

1. Appearance design: Novel, using spray molding technology without peeling off paint, durable and durable.

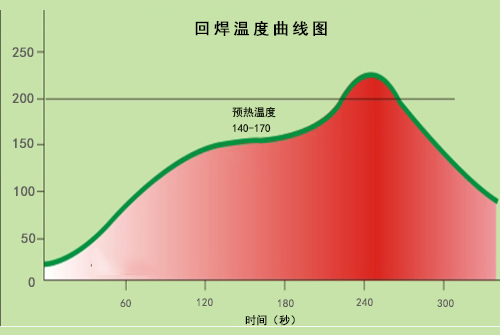

2. Hot air preheating: no blind spot hot air preheating zone, efficient heat conduction; Thick insulation layer, energy-saving and energy-saving

3. Alloy chain claw: High strength and long service life.

4. Adjustable nozzle design; The oxidation amount of tin slag is extremely low, and the liquid tin flow design principle is adopted to reduce the impact oxidation amount of tin. The wave peak can be adjusted with the width of the PCB board, greatly reducing the oxidation amount of tin when welding small PCB boards. The adjustable distance is 70-250MM.

5. Transmission mechanism: Adopting precise modular design, accurate transmission, long service life, and easy maintenance.

6. Transportation system: closed-loop control. Stepless speed regulation, precise control of PCB preheating and welding time.

7. Heating system: The temperature adopts PID closed-loop control, ensuring stable and reliable temperature control.

8. Flux spray device: stepping motor closed-loop automatic tracking spray system, spray width and spray time can be automatically adjusted, and advance and extend spray time can be set as required; Isolation design, pull-out and detachable, easy to clean and maintain;

9. Control system: Intelligent control program, using branded electrical appliances to ensure stable equipment operation.

10. Human machine interface: Adopting brand touch screen to ensure system reliability and stability.

11. Automatic switch on/off: can be carried out according to the date, time, and temperature control parameters set by the user.

12. Fault prompt: Self diagnosis of system faults, automatic display of causes, and troubleshooting methods available at any time.

13. Economic operation: Automatic spraying of flux through the board, automatic peaking, minimizing the use of flux and the oxidation of tin.

14. Protection system: Short circuit and overcurrent protection, providing protection for key electrical components of the equipment.

Technical parameters:

|

PCB board width range |

Max.50~250mm |

|

PCB board transportation height |

750±50mm |

|

PCB board transportation speed |

0~2000mm/Min |

|

PCB board transportation angle (welding angle) |

3~7linear measure |

|

PCB board transportation direction |

L→R/R→L(optional) |

|

Height limit of components on PCB board |

Max.100mm |

|

Peak height range |

0—12mm Adjustable and maintains peak balance |

|

Wave number |

2 |

|

Length of preheating zone |

350×2=700mm |

|

Number of preheating zones |

2 |

|

Preheating zone power |

3.5×2=7kw |

|

Preheating zone temperature |

Room temperature~250 ℃ can be set |

|

Heating method |

Hot air |

|

Applicable solder type |

Lead free solder/regular solder |

|

Tin furnace power |

6kw |

|

Tin melting capacity of tin furnace |

Approx.120kg |

|

Solder temperature |

Room temperature~300 ℃, control accuracy ± 1-2 ℃ |

|

Temperature control method |

P.I.D+SSR |

|

Whole machine control mode |

PLC+Touch Screen |

|

Flux storage tank |

Max5.2L |

|

Flux flow rate |

10~100ml/min |

|

Spray movement mode |

stepping motor |

|

Power supply |

3-phase 5-wire system 380V |

|

Starting power (total power) |

max.13kw |

|

Normal operating power |

Approx.2kw |

|

Air source |

4~7KG/CM2 |

|

Rack size |

L1450×W1050×H1450mm |

|

External dimensions |

L2300×W1100×H1550mm |

|

Weight |

Approx800kg |

Product

Product

home

home

TEL:0510 - 81029991

TEL:0510 - 81029991 Mail:changqixiao@163.com

Mail:changqixiao@163.com Address:No. 189, Changba Road, Chang'an, Yanqiao Street, Huishan District, Wuxi City

Address:No. 189, Changba Road, Chang'an, Yanqiao Street, Huishan District, Wuxi City